Scientific injection molding has its set of principles that have become the innovative benchmark in plastic injection molding. However, as some experts in the industry indicate, there are some forms of waste that people can expect when it comes to scientific injection molding. Plastic injection molding or SIM controls them all.

Transportation

It is on finishing and sorting areas that the traditional plastic injection molding would rely on and unplanned transportation for receiving and shipping purposes. Scientific injection molding can consistently provide high-quality predictable yields with limited waste, eliminating the added transportation of molds and products.

Excess Inventory

Overproduction leftovers can become excess inventory that ultimately is waste. Even if people can sell the parts, they will need to transport and store them until they can ship them. Scientific injection molding ensures predictable runs with dependable yields and drastically reduced waste.

Wait Time

The production process may not result in only the waste of product and capital; it is possible to waste time also. With scientific injection molding, the manufacturing action tends to be pretty sufficient when optimized. It is easy to eliminate the wait time to switch machines, marvelous molds, and inspect production results. Using scientific analysis for plastic injection molding entails the complete process and time of the cycles to deliver outstanding efficiency and less waste.

Excess Movement

Scientific injection molding prevents the waste of excess movement by streamlining the production process. The result of an optimized molding process is lean manufacturing and gets rid of wasted motion by machines and personnel alike.

Overproduction

Manufacturers typically have to shoot more parts than the order they called for to compensate for unforeseen issues or defects. However, scientific injection molding principles can optimize the process. As such, the production tends to be accurate and predictable, saving resources and money by eliminating overproduction.

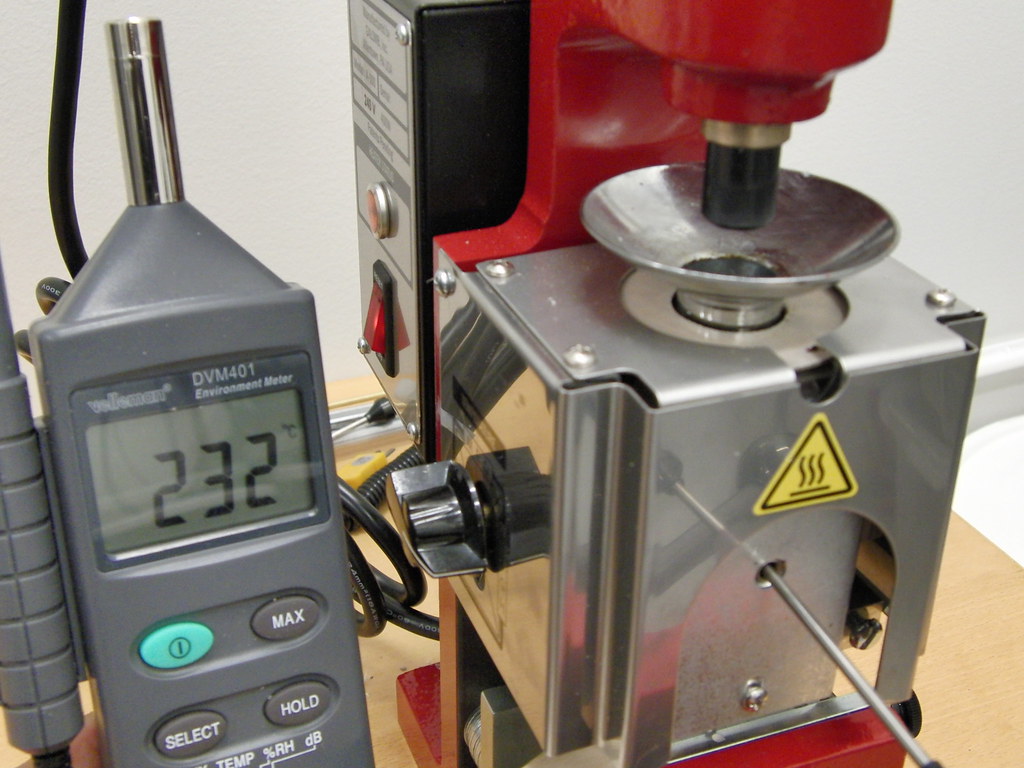

Over Processing

It is possible for scientific injection molding to measure the cavity and ensure it is balanced to eliminate the waste of the old shoot and tweak the process. Professionals can remove the practice of overprocessing from the manufacturing line completely without this long-accepted waste of material. They can run a series of data collecting baseline tests on the mold to assist in controlling the variables that add to overprocessing. According to Patel and Staples, the process is typical of a doctor taking the crucial symptoms to establish a baseline for any possible treatments required.

Defective Production

When they prevent defects before the mold even initiates production, it is easy to eliminate the defective products. In addition, scientific injection molding can discover the production mold defect potentials in the process development phase providing precise information to minimize the chance of faulty parts.

The plastic injection molding invention has dragged classical business practice into the future and revolutionized manufacturing. Injection molding has since spread throughout the industry and has become integral to families, health, and businesses. Yet, scientific injection molding comes in even when such a massive advancement in manufacturing can use improvement.